-40%

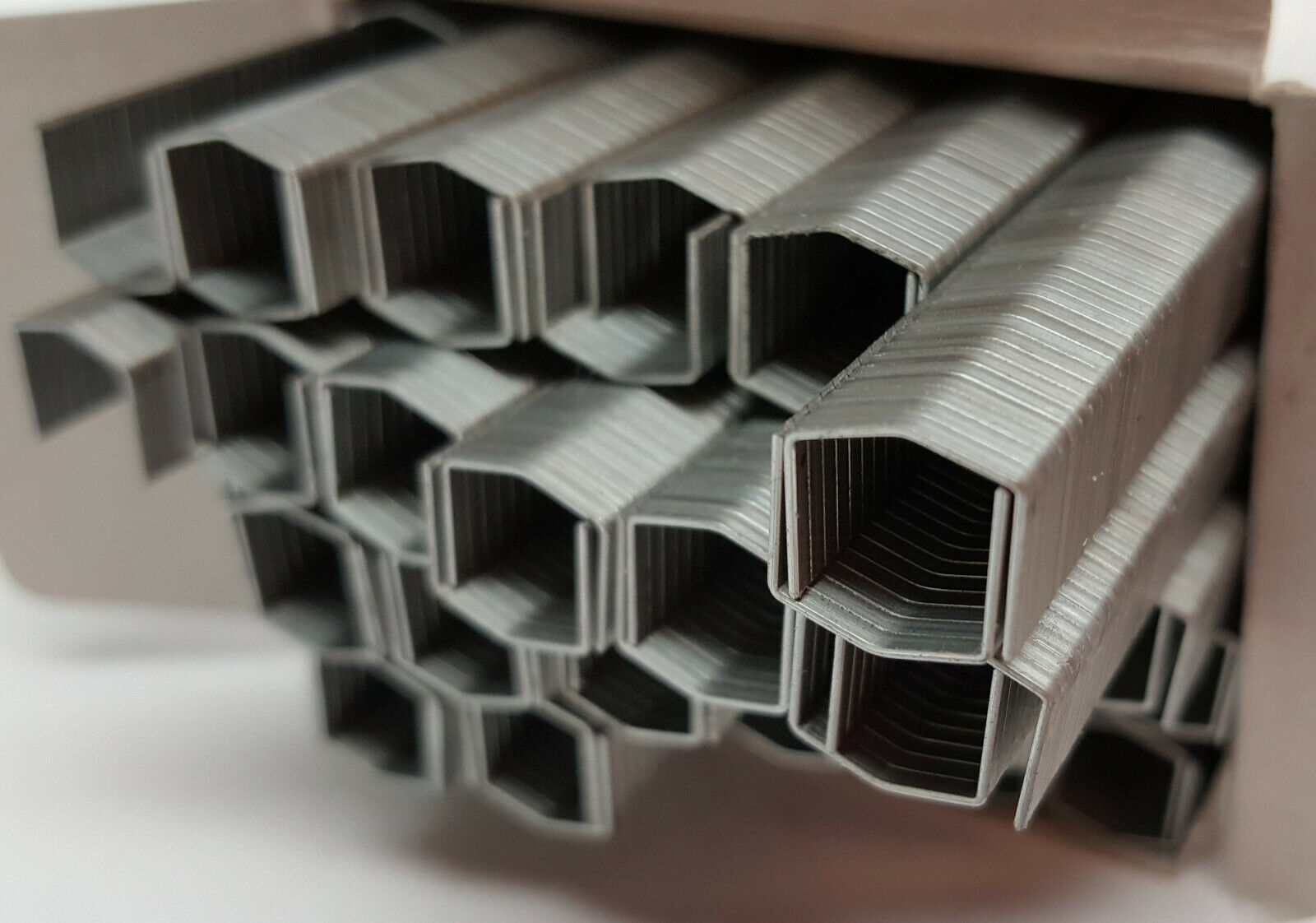

New Wave Chair Co 316 Stainless Steel Divergent Point Staples

$ 12.64

- Description

- Size Guide

Description

Brand: New Wave Chair CoItem: 316 Stainless Steel Divergent Point Staples

Size: 1/2" Crown + 3/8" Length

Quantity: 5,000 per box

Type

316 steel

is an austenitic chromium-nickel

stainless steel

that contains between two and 3% molybdenum. The molybdenum content increases corrosion resistance, improves resistance to pitting in chloride ion solutions, and increases strength at high temperatures.

Did you know that 304 and 316 are the most popular and widely used types of stainless steel? From the naked eye, it can be extremely difficult to tell the difference between grades of stainless steel. 304 and 316, in particular, look almost identical and the differences between the two are easy to miss. So what are the differences between 304 vs 316 stainless steel?

The most basic difference between the grades of steel is the presence of

molybdenum

in stainless 316. Molybdenum is a chemical element used for the strengthening and hardening of steel. Its main function in stainless 316 is to help fight off corrosion from chlorides. Stainless 316 contains more nickel than stainless 304, while 304 contains more chromium than 316. Stainless 304 usually consists of 18% chromium and 8% nickel. Stainless 316 is made up of 16% chromium, 10% nickel and 2% molybdenum.

The two steel grades are comparable in appearance, chemical makeup and characteristics. Both steels are durable and provide excellent resistance to corrosion and rust. 304 stainless steel is the most versatile and widely used austenitic stainless steel in the world, due to its corrosion resistance. 304 stainless is also cheaper in cost compared to 316, another reason for its popularity and widespread use.

Stainless 316 is more expensive because it provides a higher corrosion resistance, especially against chlorides and chlorinated solutions. This makes stainless 316 more desirable in applications where salt exposure is an issue. If you have an application with powerful corrosives or chlorides, the extra cost of stainless 316 is highly recommended. In such applications, 316 stainless will last longer than 304, providing you with extra years of life and usage. If your application uses milder acids or does not contain salt exposure, stainless 304 is perfect. Below we list some common applications for both grades of steel.

Applications for 316 Stainless Steel

Stainless Steel Floats

Marine parts

Outdoor electrical enclosures

Chemical Equipment

Pharmaceutical equipment